Cool run: liquid metal polymers heat up electronics performance

GA, UNITED STATES, October 31, 2024 /EINPresswire.com/ -- In the quest for more efficient electronic devices, heat dissipation has become a critical issue. A new study presents a significant advancement in the preparation of thermal conductive polymer composites containing liquid metal, offering a solution to the persistent challenge of heat management in high-power electronics.

Effective thermal management is essential to ensuring the performance and lifespan of modern electronics. While polymers are widely used in electronic components, they inherently exhibit poor thermal conductivity, limiting their effectiveness in dissipating heat. To overcome this, researchers have been investigating the potential of integrating highly conductive fillers, such as liquid metals (LM), into polymers. However, stable dispersion and strong interfacial bonding between polymer matrices and liquid metal fillers have proven difficult to achieve, underscoring the need for further research into advanced composite materials capable of enhancing thermal properties while maintaining mechanical integrity.

A team from Sichuan University, led by Professor Hua Deng, published a study (DOI: 10.1007/s10118-024-3144-2) in the Chinese Journal of Polymer Science on May 21, 2024, showcasing a new method for producing high-performance polymer composites containing liquid metal. The researchers developed a novel technique that significantly improves the thermal conductivity of polymers by enhancing the interaction between liquid metal particles and the polymer matrix. Their findings provide valuable insights into addressing the heat dissipation requirements of high-power electronics.

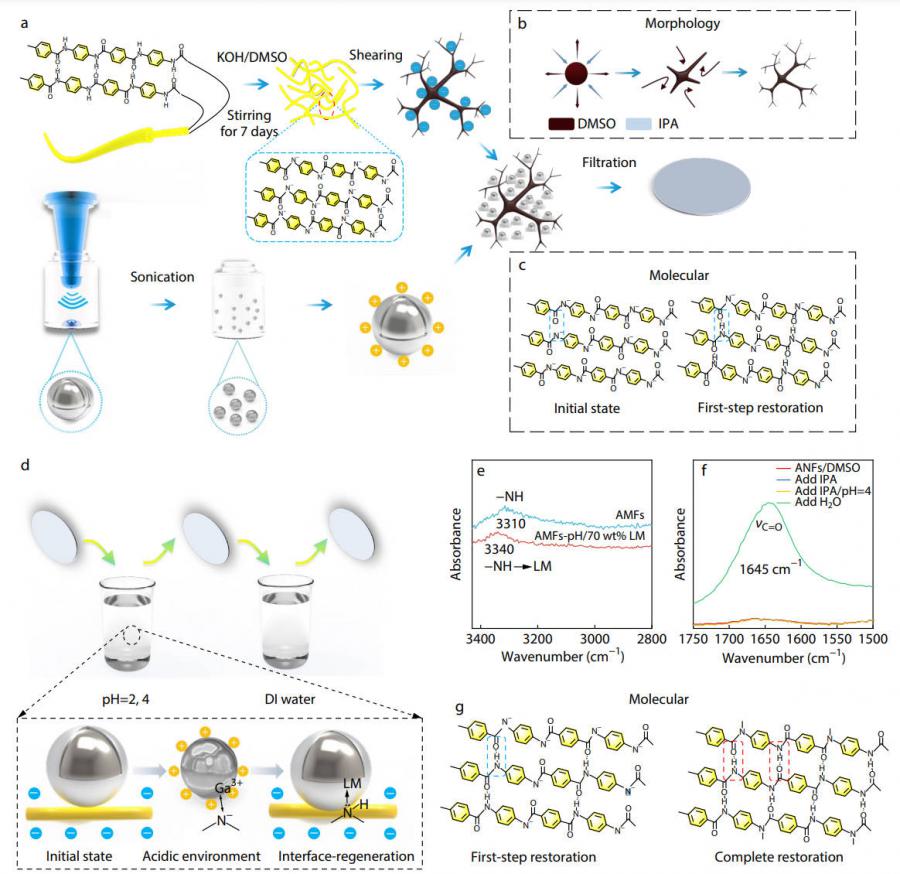

The study introduces a new process called "shear-induced precipitation-interfacial reset-reprotonation." This innovative approach successfully disperses liquid metal particles within the polymer matrix, overcoming previous challenges related to particle dispersion and interfacial compatibility. The team used aramid micron fibers (AMFs) as the foundation for their composites, inspired by the dendritic structure of tree roots to enhance stability and dispersion. By carefully controlling pH during protonation, the researchers ensured optimal bonding between AMFs and liquid metal particles. The resulting AMFs-pH/LM films achieved a thermal conductivity of 10.98 W·m−1·K−1, a 126.8% improvement over conventional polymer composites. Additionally, the films demonstrated excellent mechanical properties, including a tensile strength of approximately 85.88 MPa, making them ideal for use in high-power electronics where durability and efficient heat dissipation are crucial. This advancement represents a significant step forward in the development of multifunctional polymer composites for industrial applications.

"Our approach not only enhances the thermal conductivity of polymer composites but also preserves their mechanical strength," said Professor Hua Deng, the study’s lead author. "By stabilizing liquid metal particles within the polymer matrix, we are opening new possibilities for materials used in electronics and other industries where effective heat management is critical. This technique could lead to more efficient thermal management solutions in the future."

The potential applications of this research extend far beyond electronics. The AMFs-pH/LM composite films could be utilized in industries requiring materials that withstand both mechanical stress and efficient heat dissipation, such as high-power light emitting diode (LED) lighting, flexible electronics, and wearable devices. Furthermore, the innovative method presented in the study could inspire new advances in composite material design, paving the way for more sustainable and energy-efficient solutions across various technology sectors.

DOI

10.1007/s10118-024-3144-2

Original Source URL

https://doi.org/10.1007/s10118-024-3144-2

Funding information

This work was financially supported by the National Key Research & Development Plan (No. 2022YFA1205200).

Lucy Wang

BioDesign Research

email us here

Distribution channels: Chemical Industry, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release