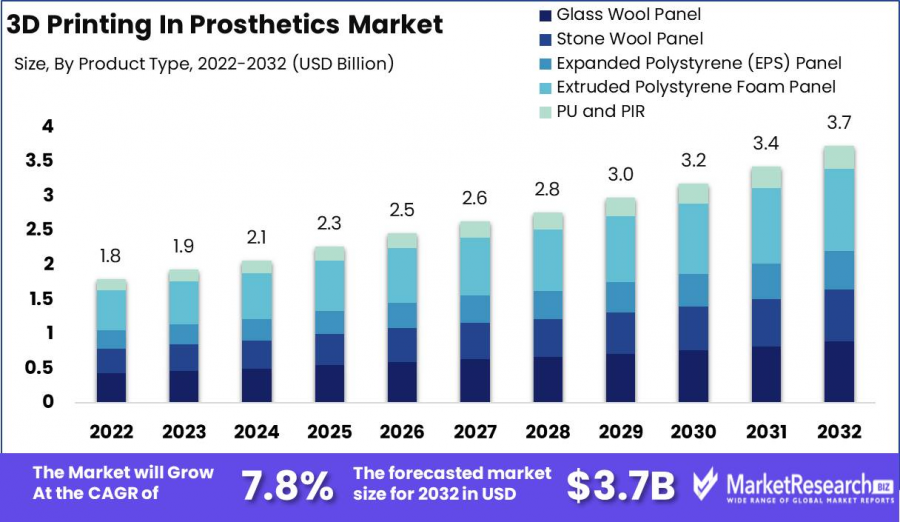

3D-Printed Prosthetics Market Expected to Register USD 3.7 Billion by 2032 Grow With 7.8% CAGR

Global 3D Printing in Prosthetics Market size is expected to be worth around USD 3.7 Bn by 2032 from USD 1.8 Bn in 2022, growing at a CAGR of 7.8%

NEW YORK, NY, UNITED STATES, February 19, 2025 /EINPresswire.com/ -- Overview

Global 3D Printing in Prosthetics Market size is expected to be worth around USD 3.7 Bn by 2032 from USD 1.8 Bn in 2022, growing at a CAGR of 7.8% during the forecast period from 2023 to 2032.

The prosthetics industry is undergoing a major transformation with the integration of 3D printing technology. This innovation allows for the rapid production of custom prosthetic limbs, improving affordability, accessibility, and patient comfort. Unlike traditional prosthetics, which are time-consuming and expensive to produce, 3D printing enables the creation of lightweight and highly personalized designs at a lower cost.

One of the key advantages of 3D-printed prosthetics is customization. With precise digital scanning, prosthetic limbs can be tailored to fit individual patients perfectly, enhancing mobility and reducing discomfort. Additionally, the technology supports the use of durable and biocompatible materials, ensuring long-lasting and functional solutions.

3D printing has also accelerated the development of prosthetics for children, who require frequent adjustments due to growth. The cost-effectiveness of this approach makes high-quality prosthetics more accessible to underserved communities. Furthermore, researchers are exploring the integration of smart sensors and robotics into 3D-printed prosthetics, advancing functionality and control.

As the demand for innovative healthcare solutions grows, 3D printing continues to play a crucial role in the evolution of prosthetics. This technology is not only reshaping lives but also setting new standards for patient-centric care.

Click here to get a Sample report copy @ https://marketresearch.biz/report/3d-printing-in-prosthetics-market/request-sample/

Key Takeaways

- The global 3D printing in prosthetics market is projected to reach USD 3.7 billion by 2032, registering a compound annual growth rate (CAGR) of 7.8% over the forecast period.

- An estimated 40 million individuals worldwide require prosthetic limbs and orthopedic devices due to congenital conditions, accidents, diseases, and conflict-related injuries.

- The Asia-Pacific region currently holds a 34.3% revenue share in the global market, lower than North America and Europe, but is expected to witness steady growth in the coming years.

- In 2022, Europe’s 3D printing in prosthetics market was valued at approximately USD 1.2 billion and is anticipated to expand at a CAGR of 7.4% over the forecast period.

- Among prosthetic types, the upper limb prosthetics segment is expected to hold a 33.7% revenue share, driven by increasing demand for advanced prosthetic solutions among individuals with upper limb loss worldwide.

Segmentation Analysis

•By Technology: The Fused Deposition Modeling (FDM) segment dominated the 3D printing in prosthetics market in 2022, driven by its cost-effectiveness and versatility. FDM technology enables the production of affordable prosthetic devices, making it a preferred choice for patients and healthcare providers. Additionally, FDM supports various materials, including thermoplastics and biocompatible options, allowing for customized prosthetic solutions. The ability to create durable and functional prosthetics with lower production costs continues to drive FDM market growth.

•By Prosthetic Type: The upper limb prosthetics segment accounted for the largest revenue share in 2022, fueled by design advancements and increased adoption among pediatric patients. Innovations in upper limb prosthetic designs have led to the development of more functional and aesthetically appealing devices, attracting a broader patient base. Additionally, the rising incidence of congenital upper limb deficiencies in children has increased demand for customizable, cost-effective 3D-printed prosthetics, providing an efficient solution as they grow.

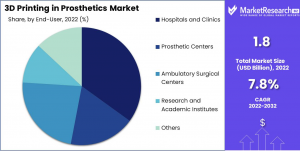

•By End-User: The hospitals and clinics segment held a significant revenue share in 2022, supported by collaborations with 3D printing companies and technological advancements. Increased partnerships between healthcare institutions and 3D printing firms are enhancing access to customized prosthetic solutions. Additionally, technological support, including training and certifications, is enabling healthcare professionals to effectively integrate 3D-printed prosthetics into patient care. These factors are driving segment growth and expanding market accessibility.

Market Segments

By Technology

•Fused Deposition Modeling (FDM)

•Stereolithography (SLA)

•Selective Laser Sintering (SLS)

•PolyJet Technology

•Others

Material Type

•Thermoplastic

•Titanium Alloys

•Photopolymer Resins

•Other Metals

Biocompatible Materials

•Prosthetic Type

•Upper Limb Prosthetics

•Lower Limb Prosthetics

•Exoskeletons

•Custom Implants

•Dental Prosthetics

End-User

•Hospitals and Clinics

•Prosthetic Centers

•Ambulatory Surgical Centers

•Research and Academic Institutes

•Others

Application

•Orthopedics

•Cranio-Maxillofacial

•Dental

•Audiology

•Others

To Purchase this Premium Report @ https://marketresearch.biz/purchase-report/?report_id=41171

Market Dynamics

•Driver: The global 3D-printed prosthetics market is primarily driven by the increasing demand for personalized medical solutions. Three-dimensional printing enables the creation of prosthetic devices tailored to the unique anatomical structures of individual patients, enhancing comfort and functionality. This customization is particularly beneficial in pediatric care, where children require prosthetics that accommodate growth and activity levels. Additionally, 3D printing offers a cost-effective alternative to traditional manufacturing methods, reducing production time and expenses, thereby making prosthetic devices more accessible to a broader population. These factors collectively propel the market's growth.

•Trend: A notable trend in the 3D-printed prosthetics market is the integration of biocompatible materials and multi-material printing techniques. Advancements in 3D printing technology have facilitated the use of materials that closely mimic natural tissue properties, improving the durability and comfort of prosthetic devices. Moreover, the development of multi-material printers allows for the fabrication of prosthetics with varying material properties in a single print, enhancing functionality. This trend reflects a shift towards more sophisticated and life-like prosthetic solutions, aligning with the evolving needs of patients and healthcare providers.

•Restraint: Despite its potential, the adoption of 3D-printed prosthetics faces challenges, particularly concerning regulatory approvals and standardization. The medical field requires rigorous testing and validation to ensure the safety and efficacy of prosthetic devices. The relatively nascent stage of 3D printing technology in healthcare means that standardized protocols are still under development, leading to potential delays in product approval and market entry. Additionally, the initial setup costs for 3D printing facilities and the need for specialized training can be prohibitive for some healthcare providers, limiting widespread adoption.

•Opportunity: The 3D-printed prosthetics market presents significant opportunities, particularly in addressing the global shortage of affordable prosthetic devices. In low-resource settings, traditional prosthetics are often inaccessible due to high costs and limited availability. Three-dimensional printing offers a scalable solution to produce cost-effective, customized prosthetics locally, reducing dependency on imports and extensive supply chains. Furthermore, ongoing research into bioprinting and the use of advanced biomaterials holds promise for developing prosthetics that integrate seamlessly with human tissue, potentially improving patient outcomes and expanding the market's scope.

Market Key Players

•Stratasys Ltd.

•3D Systems Corporation

•EOS GmbH Electro Optical Systems

•EnvisionTEC

•Materialise NV

•Formlabs Inc.

•Stryker Corporation

•Limbitless Solutions

•Open Bionics

•UNYQ

•Ottobock

•ProPellor

•Bespoke Innovations

•SHINING 3D Tech Co., Ltd.

•3D LifePrints

•LayerWise NV (3D Systems)

•The Exo-Prosthetic Center

•Mecuris GmbH

•nTopology Inc.

•PrinterPrezz Inc.

Regional Analysis

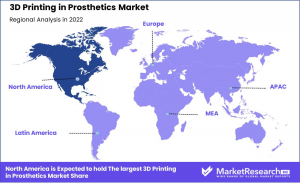

North America holds the largest revenue share in the global 3D printing in prosthetics market, driven by advanced healthcare infrastructure, high awareness, and demand for personalized prosthetic solutions. The region benefits from strong research and development funding, collaborations between healthcare providers and 3D printing companies, and rapid technological advancements. Additionally, over 45,000 American veterans live with limb loss, increasing demand for specialized in-home prosthetic care. Government initiatives, insurance coverage expansion, and academic-industry partnerships are expected to further fuel market growth.

Europe is another key market, supported by well-established healthcare systems, an aging population, and proactive adoption of innovative medical technologies. The region is witnessing technological advancements in biocompatible materials, improving the durability and functionality of 3D-printed prosthetics. European Union initiatives for standardized regulations and research funding are driving further innovation. Private and public investments in healthcare technologies are also accelerating market expansion.

Asia-Pacific presents significant growth potential, with rising healthcare expenditures, a large population, and economic development contributing to market expansion. Technological advancements and a focus on affordable healthcare solutions are fostering innovations in prosthetic development. Additionally, regional government collaborations with international organizations are improving healthcare accessibility and modernizing prosthetic manufacturing, driving further revenue growth in the region.

Emerging Trends in 3D-Printed Prosthetics

••Customization and Personalization: 3D printing enables the creation of prosthetic devices tailored to an individual's unique anatomy, enhancing comfort and functionality. This approach allows for the production of patient-specific implants and prosthetics, leading to better fit and user satisfaction.

••Cost Reduction and Accessibility: Traditional prosthetics can be expensive and time-consuming to produce. 3D printing offers a more affordable and faster alternative, making prosthetic devices more accessible, especially in low-income regions.

••Advancements in Materials: The development of new materials suitable for 3D printing, such as biocompatible polymers and metals, has expanded the possibilities for creating durable and functional prosthetic limbs. These materials contribute to the production of prosthetics that closely mimic the properties of natural limbs.

••Integration of Technology: Modern 3D-printed prosthetics are increasingly incorporating advanced technologies, such as sensors and robotics, to provide users with enhanced control and feedback. This integration leads to more intuitive and responsive prosthetic devices.

Use Cases of 3D-Printed Prosthetics

••Medical Applications: 3D-printed prosthetics are being utilized to create customized limbs for amputees, improving their mobility and quality of life. For instance, Open Bionics, a UK-based company, develops affordable, 3D-printed bionic arms tailored to individual users, enhancing both functionality and aesthetics.

••Rehabilitation in Conflict Zones: In regions affected by conflict, such as Ukraine, 3D printing technology has been employed to produce prosthetic limbs for soldiers who have suffered amputations. This approach allows for rapid production and fitting of prosthetics, aiding in the rehabilitation process.

••Pediatric Prosthetics: Children require prosthetics that accommodate growth and activity levels. 3D printing offers a cost-effective solution for producing lightweight, customizable prosthetic limbs for children, allowing for adjustments as they grow.

••Facial Prosthetics and Reconstruction: Beyond limb replacement, 3D printing is utilized in creating facial prosthetics for individuals who have suffered injuries or undergone surgeries. This application includes the production of prosthetic eyes and other facial features, contributing to improved aesthetics and self-esteem.

Explore More Healthcare Reports

Clear Aligners Market-https://marketresearch.biz/report/clear-aligners-market/

Sexual Wellness Market-https://marketresearch.biz/report/sexual-wellness-market/

Nuclear Imaging Devices Market-https://marketresearch.biz/report/nuclear-imaging-devices-market/

Steam Autoclaves Market-https://marketresearch.biz/report/steam-autoclaves-market/

Respiratory Care Devices Market-https://marketresearch.biz/report/respiratory-care-devices-market/

Hearing Loop Market-https://marketresearch.biz/report/hearing-loop-market/

Gonorrhea Testing Market-https://marketresearch.biz/report/gonorrhea-testing-market/

Galactosemia Treatment Market-https://marketresearch.biz/report/galactosemia-treatment-market/

Fungal Infections Market-https://marketresearch.biz/report/fungal-infections-market/

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Distribution channels: Healthcare & Pharmaceuticals Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release