Electric Vehicle Adhesives Market Demand to Grow By 39.30% CAGR through 2032 | Research by SNS Insider

Electric Vehicle Adhesives Market

Electric Vehicle Adhesives Market Drives Innovation with Advanced Formulations and Sustainable Solutions for Lightweight, High-Performance EV Manufacturing.

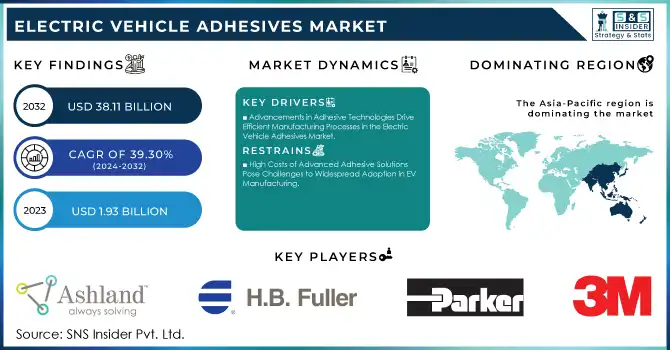

AUSTIN, TX, UNITED STATES, January 20, 2025 /EINPresswire.com/ -- The global electric vehicle (EV) adhesives market, valued at USD 1.93 billion in 2023, is projected to reach USD 38.11 billion by 2032, growing at a compound annual growth rate (CAGR) of 39.30% during the forecast period from 2024 to 2032.

The growth of the EV adhesives market is primarily driven by the increasing demand for lightweight, energy-efficient vehicles and the advancements in adhesive technologies. As electric vehicles gain popularity, manufacturers are turning to innovative adhesive solutions that enhance vehicle performance, improve energy efficiency, and contribute to the overall reduction of vehicle weight.

A significant driver for market growth is the rising adoption of electric vehicles, as governments worldwide implement stringent emission regulations and offer incentives for EV production and sales. Adhesives play a crucial role in the EV manufacturing process by providing essential bonding for critical components such as battery packs, interiors, and exteriors. The ongoing focus on improving vehicle range and battery performance is boosting the demand for specialized adhesives that offer high bonding strength, durability, and resistance to environmental factors.

Additionally, the increasing trend towards sustainable and eco-friendly materials in EVs is further propelling the demand for adhesive solutions. The use of advanced adhesives is essential for replacing traditional fasteners, welding, and mechanical fastening methods, which can add weight and reduce energy efficiency. These adhesives also contribute to improved safety by ensuring the secure assembly of vehicle parts and providing protection to sensitive components, such as the battery, from external stress and vibration.

Get a Sample Report of Electric Vehicle Adhesives Market @ https://www.snsinsider.com/sample-request/2367

Prominent Key Players Included are:

• 3M (3M Scotch-Weld Epoxy Adhesive DP420, 3M DP8810NS Structural Adhesive)

•Ashland Inc. (AquaPolymers, Hexion EPON Resin)

• DAP Global Inc. (DAP 3.0 Sealant, DAP Premium Clear Sealant)

• B. Fuller (FullerBond 2168, FullHPR 2101)

• Henkel AG & Co. KGaA (Loctite EA 3472, Loctite 9460)

• Illinois Tool Works Inc. (ITW Devcon 5 Minute Epoxy, ITW Plexus MA300)

• Kingspan Group (Kingspan Tarec Adhesive, Kingspan SF100)

• LOCTITE (part of Henkel AG & Co. KGaA) (Loctite 406, Loctite EA 3478)

• Paroc Group (Paroc XPS Sealant, Paroc Firestop Systems)

• Parker Hannifin Corporation (Parker LORD 201, Parker LORD 200)

• Permabond (Permabond ET500, Permabond A136)

• PPG Industries, Inc. (PPG Lamineer 8150, PPG ULTRA-STRIKE adhesive)

• Sika AG (SikaPower 4720, Sikaflex-221)

• Specialty Polymer Co. (SPC-SS-GD, SPC-HS-300)

• Sherwin-Williams Company (Sherwin-Williams 3M Adhesives, Sherwin-Williams 10-300)

• Texwipe (part of ITW) (Texwipe DuraClean Adhesive, Texwipe CleanSeal)

• The Dow Chemical Company (Dowsil 732 Sealant, Dow Adhesive D-521)

• Trelleborg AB (Trelleborg Engineering Adhesives, Trelleborg Sealing Solutions)

• Wacker Chemie AG (Wacker Elastosil, Wacker SilGel)

• Weicon GmbH & Co. KG (Weicon Sealant, Weicon Bond 300)

Segmental Analysis

By Resin Type

• Epoxy

• Polyurethane

• Silicone

• Acrylic

• Others

The epoxy resin segment with a share of 38% in 2023. Mainly in the automotive industry, epoxy adhesives are recognized for their superior mechanical strength, durability, and high adhesion properties on a wide range of substrates. This makes them highly more suitable for the electric vehicle applications where they need to travel through gross environmental conditions along with extreme temperatures and exposure to various chemicals. Epoxy adhesives, for example, are often used in battery assembly and structural bonding, so that the components stay attached and do not break off in the use. For example, Henkel and 3M, have developed new epoxy formulations that fulfill all the requirements of well-performing electric vehicles but also help the industry move towards low VOC emissions, reducing processing times and offer improvements in other metrics needed for applications.

By Substrate

• Plastic

• Composite

• Metals

• Others

The composite substrate segment accounted for 40% of the global market in 2023. Composites are gradually being used in the automotive industry since their lightweight and strong properties improve electric vehicle performance and efficiency significantly. Composite materials reduce the weight of the vehicle, reducing the energy consumption and the distance of travel of the electric vehicle. Composites have their own proprietary adhesives that provide a high level of bonding needed in structural components and body panels. Some manufacturers, including DuPont and H.B. Fuller, are developing adhesives that address the requirements presented by composite materials, including different thermal expansion rates and surface preparation, etc. Such developments in the adhesive technology ensure that these bonds are strong and can survive under the various operating environment stresses.

By Application

• Powertrain System

• Optical Element

• Sensors & Communication

• Body Frame

• Others

The electric vehicle adhesives market was led by type powertrain system, having a market share of 30% in 2023. Powertrain systems have electric motors and battery systems, as well as drivetrains, all of which require secure assembly with adhesives when reliability and performance are critical. They are also evolving too, as the need for robust, heat- and/or mechanical stress-tolerant high-performance adhesives has spurred a number of innovative new adhesive formulations targeting specifically powertrain components. Major companies like Henkel and Lord Corporation have an array of specialty adhesive solutions that address the specific challenges when bonding powertrain systems to help ensure various components are fastened durable/secure to optimize electric vehicle performance and safety.

By Vehicle Type

• Battery Electric Vehicle (BEV)

• Plug-in Hybrid Electric Vehicle (PHEV)

• Hybrid Electric Vehicle (HEV)

By Form

• Liquid

• Film & Tape

• Others

Buy Full Research Report on Electric Vehicle Adhesives Market 2024-2032 @ https://www.snsinsider.com/checkout/2367

Regional Analysis

Asia Pacific held the largest market share of around 45% in the EV adhesives market in 2023. The region’s dominance can be attributed to the rapid growth of electric vehicle production in countries such as China, Japan, South Korea, and India. China, in particular, is the largest market for electric vehicles and accounts for a significant portion of global EV sales. The Chinese government’s efforts to support the transition to electric mobility through incentives, subsidies, and stringent emission standards have contributed to the expansion of the EV market, thereby driving the demand for adhesives.

The increasing shift toward electric vehicle production in India and Southeast Asia is also expected to fuel the demand for EV adhesives in the coming years. Furthermore, countries like Japan and South Korea are leaders in battery technology and the automotive industry, making them key markets for adhesive solutions in the EV sector.

Recent Developments

• April 2024: Henkel AG announced the launch of a new range of high-performance structural adhesives designed for electric vehicle battery pack assembly. The new adhesives offer improved thermal conductivity and enhanced bonding strength, ensuring the safety and performance of EV battery systems.

• March 2024: 3M introduced a new series of electric vehicle adhesives that provide lightweight and durable bonding solutions for exterior components. These adhesives are formulated to withstand the extreme temperatures and environmental stresses faced by electric vehicles, helping manufacturers reduce vehicle weight without compromising on performance.

• January 2024: Dow Inc. expanded its research and development capabilities with a focus on developing next-generation adhesives for electric vehicle applications. The company’s new line of adhesives is expected to enhance the durability and safety of electric vehicle components, including the battery, body, and interior parts.

Table of Contents:

1. Introduction

2. Executive Summary

3. Research Methodology

4. Market Dynamics Impact Analysis

5. Statistical Insights and Trends Reporting

6. Competitive Landscape

7. Electric Vehicle Adhesives Market Segmentation, By Resin Type

8. Electric Vehicle Adhesives Market Segmentation, By Vehicle Type

9. Electric Vehicle Adhesives Market Segmentation, By Substrate

10. Electric Vehicle Adhesives Market Segmentation, By Form

11. Electric Vehicle Adhesives Market Segmentation, By Application

12. Regional Analysis

13. Company Profiles

14. Use Cases and Best Practices

15. Conclusion

Speak with Our Expert Analyst Today to Gain Deeper Insights @ https://www.snsinsider.com/request-analyst/2367

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Akash Anand

SNS Insider | Strategy and Stats

+1 415-230-0044

email us here

Visit us on social media:

Facebook

X

LinkedIn

Instagram

YouTube

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release