Flow Battery Technology Advancement: Simultaneous Production of Cathode Materials and Supercapacitors

Flow battery technology may soon include simultaneous production of cathode materials and supercapacitors.

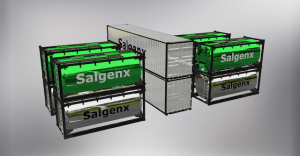

MADISON, WISCONSIN, USA, July 31, 2023/EINPresswire.com/ -- Salgenx, a pioneering leader in energy storage solutions, is revolutionizing the battery industry with a groundbreaking development. They are developing a process that enables flow batteries to manufacture cathode materials while charging. This innovative breakthrough promises to bring about rapid production of cathode materials at reduced costs and significantly faster production times.

The concept of a battery producing its own battery materials during charging is as fascinating as robots manufacturing their own parts and assembling them. Salgenx's revolutionary process allows flow batteries to harness this capability, creating a vast universe of manufacturing possibilities. Notably, it includes the production of graphene, carbon nano-onions, and various other cathode materials for both batteries and supercapacitors.

These cathode materials hold immense importance, not only for the evolution and production of flow batteries but also for supercapacitors (and ultracapacitors). Supercapacitors play a vital role in enabling swift integration of flow batteries into grid-based storage systems. In contrast to traditional lithium-based storage systems, the inherent slower discharge of flow batteries posed a challenge for grid-based peaker plants. However, with the introduction of ultracapacitors, the scenario changes drastically, allowing faster discharge of energy.

A newly designed supercapacitor by The University of Texas at El Paso utilizes a material with a carbon nano-onion (CNO) core structure, creating multiple pores that significantly increase energy storage capacity. This breakthrough brings supercapacitors closer to achieving high energy density, which would revolutionize energy storage and management.

This revolutionary manufacturing method, coupled with the inherent advantages of flow batteries, opens the door to faster production and deployment into the market. Salgenx is at the forefront of this remarkable development, and they envision a future where battery cathode materials can be manufactured on-demand through the implementation of AI-driven just-in-time manufacturing.

"We are thrilled to develop this cutting-edge technology that will redefine energy storage systems. The simultaneous production of cathode materials and supercapacitors during charging represents a significant leap forward in battery innovation," said Greg Giese, CEO at Salgenx. "Our vision is to provide a seamless transition to a greener and more efficient energy future."

With this groundbreaking advancement, Salgenx aims to accelerate the adoption of flow battery technology in various sectors, including renewable energy integration, grid-based energy storage, and industrial applications. The implications of this development are poised to revolutionize energy storage and drive sustainable energy solutions forward.

Salgenx has recently published the "Salgenx Saltwater Redox Flow Battery Technology Review," a comprehensive report detailing the advancements and capabilities of their innovative energy storage technology along with simultaneous production of graphene, cathode materials, and carbon nano-onions (CNO). The report provides an in-depth analysis of flow battery technology including ultracapacitors and their possible applications in a saltwater battery system. It highlights the benefits of combining ultracapacitors and redox flow batteries, offering valuable insights into the future of grid-scale energy storage. The report is available through Infinity Turbine website: https://www.infinityturbine.com

Salgenx, a division of Infinity Turbine LLC is committed to advancing the development of this innovative technology through collaboration with industry partners, academic institutions, and government agencies. The company anticipates pilot projects and commercial deployments in the future when funding becomes available, contributing to the global transition towards a clean and sustainable energy infrastructure.

About Salgenx:

Salgenx is a leading provider of advanced energy storage solutions. The company specializes in developing innovative technologies and products that address the challenges of grid integration, renewable energy storage, and peak power management. Salgenx is committed to driving the adoption of sustainable energy solutions to build a greener and more resilient future.

Contact: Greg Giese | CEO | Infinity Turbine LLC | greg@infinityturbine.com | greg@salgenx.com

Infinity Turbine Website: https://www.infinityturbine.com

Saltwater Battery Website: https://salgenx.com

Saltwater Battery Technology Report: https://infinityturbine.com/flow-battery-technology-report.html

Gregory Giese

Infinity Turbine LLC

+1 608-238-6001

email us here

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.