Stuck in red, shipbreaking slow to turn green

Transitioning from dangerous and polluting shipbreaking yards to green ship recycling facilities remains a priority, particularly as key deadlines loom, but the sluggish pace of progress continues to delay the shift in Bangladesh.

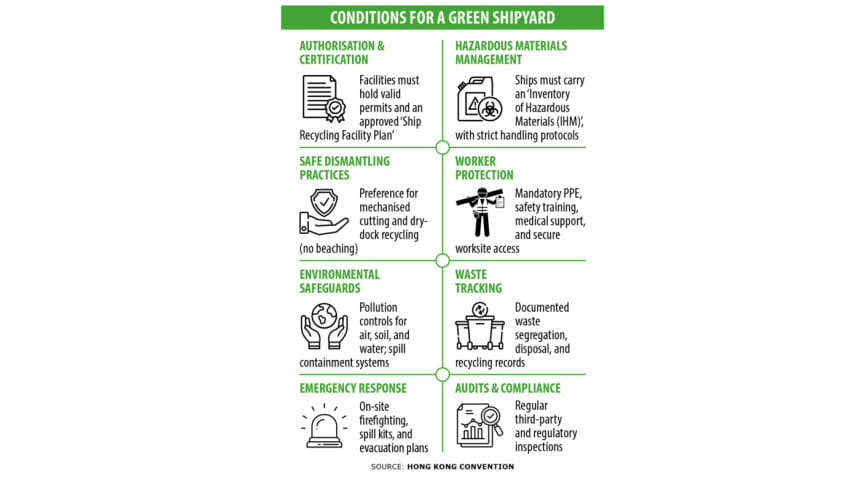

This lack of impetus is not only causing environmental harm but also creating serious business challenges, especially as Bangladesh must shift to green ship recycling by June 2025 in accordance with the Hong Kong Convention or run the risk of others refusing to send vessels to the country.

Bangladesh began the green transition in 2017, when PHP Ship Recycling Yard became the first entity in the country to receive international green certification.

Yet, only seven shipbreaking yards in the country have received similar certification as of March this year, according to the Bangladesh Ship Breakers and Recyclers Association (BSBRA).

To put things in perspective, the country has 248 shipbreaking yards, as per data from the Department of Inspection for Factories and Establishments. However, only 30 to 35 of these shipbreaking yards are operational due to various reasons, according to the BSBRA.

Taslim Uddin, owner of KR Ship Recycling, a green yard, told The Daily Star that the slow transition is due mainly to a lack of financial incentives.

For example, he mentioned that converting a small yard into a green shipyard currently requires an investment of Tk 30 to Tk 40 crore.

"In return, it may take at least 10 to 12 years or more to recover this amount through profits, which reflects the slow return and uncertainty on investment in this sector," he said.

Moreover, he added, due to the long time needed to break even and low profitability thereafter, financial institutions are often reluctant to provide loans to businesses in the shipbreaking industry.

Besides, uncertainty over the business continuity due to sudden government actions is another major factor hindering progress, he said.

After the deadline in June this year, recycling facilities located in countries that do not adhere to the HKC will be unable to receive ships for recycling.

This would jeopardise the people that are employed in the sector, totalling around 8,000 to 9,000 direct employees, according to the BSBRA and those indirectly dependent on it.

Labour rights activists say that yard owners have little incentive to convert their facilities into green shipyards as traditional methods are faster, cheaper, and require significantly less investment.

Fazlul Kabir Mintu, a long-time labour rights activist working in the shipbreaking sector, told The Daily Star, "The cost of dismantling ships in green yards is significantly higher than in traditional ones."

Since profit margins would shrink as a result, many yard owners are hesitant about the transition, he added.

Mohammed Zahirul Islam, president of the BSBRA, told The Daily Star, "The Ministry of Environment has listed our sector as high-risk, placing it on the red list. As a result, we are not eligible for green financing facilities from the Bangladesh Bank.

"Banks only provide short-term loans for purchasing ships, but they are not willing to finance the development of shipbreaking yards. This lack of financial support makes it difficult for shipbreakers to invest in green infrastructure," he added.

Bangladesh urgently needs to transition to green shipbreaking to address the serious environmental and economic challenges caused by traditional methods, which involve beaching large ships and manually breaking them apart without proper safety or environmental controls.

As a result, the surrounding environment -- land, air, and sea -- is subjected to intense pollution.

A 2010 World Bank study identified the presence of hazardous materials such as lead, chromium, cadmium, mercury, asbestos, and heavy metals in the soil of the Sitakunda coastal belt, an area known for shipbreaking.

The study estimated that from 2010 to 2030, a total of 79,000 tonnes of asbestos, 240,000 tonnes of PCB, 1,978,000 tonnes of organic liquid waste, 775 tonnes of inorganic waste, and 210,000 tonnes of ozone-depleting substances would be deposited into the soil and water of the area.

Prabal Barua, a researcher who has worked on the environmental impact of shipbreaking for years, told The Daily Star, "Waste from shipbreaking yards often seeps into the Bay of Bengal, contaminating marine ecosystems and affecting biodiversity."

Soil and groundwater contamination are particularly alarming, he added. Moreover, the air quality in surrounding regions is deteriorating due to the burning of cables, oil residues, and insulation materials, releasing carcinogenic substances.

Barua added, "Marine life is under threat as oil spills and paint residues disrupt breeding cycles in the Bay of Bengal, affecting fishing communities by reducing production."

Another major concern is that workers in traditional shipbreaking yards face some of the most dangerous working conditions in the world. Most of these labourers -- often poor and unskilled -- work without basic protective equipment such as helmets, gloves, or boots.

The dismantling process, which involves cutting through thick steel with gas torches, often occurs on unstable, oily surfaces, exposing workers to explosions. Falls from great heights and the inhalation of toxic fumes are other daily hazards.

According to the NGO Shipbreaking Platform, at least 231 workers died and over 300 were seriously injured at shipbreaking yards between 2009 and 2023.

In addition to fatal accidents, workers are regularly exposed to asbestos, lead, and toxic fumes, leading to chronic illnesses such as respiratory diseases, skin conditions, and cancer.

This stands in stark contrast with green shipbreaking facilities, which emphasise worker safety by promoting proper equipment and regulated work environments, drastically reducing accidents and long-term health risks.

"In green yards, wearing safety gear while working is mandatory, ensuring better protection for the workers," Mohammed Ali, who has been working at a green yard for nine months, told The Daily Star.

Abul Kalam, another employee of a green yard, said, "Compared to traditional yards, wages in green shipbreaking facilities are not only higher but are also paid on a regular basis, providing financial stability.

Chan Meah, another worker at a green yard, told this newspaper, "We receive annual festival bonuses, a benefit often absent at traditional yards. These improvements make green yards a safer and more rewarding place to work."

When asked what action would be taken if foreign companies stop supplying ships to traditional Bangladeshi yards after June 2025 under the Hong Kong Convention, BSBRA President Zahirul Islam said, "Some yards are in the process of transitioning to green practices. We have requested the Ministry of Industry to take measures to allow foreign companies to supply ships to both green yards and those in the process of implementing green practices.

"Otherwise, this industry will face significant challenges and may come to a standstill."

Bangladesh remained the global shipping industry's first choice for scrapping vessels in 2024, with NGO Shipbreaking Platform stating that of the 409 ships dismantled globally in 2024, 130 were taken apart in Bangladesh.

For all latest news, follow The Daily Star's Google News channel.

For all latest news, follow The Daily Star's Google News channel.

Comments