Researchers at the University of Tehran have developed a novel concrete that can be 3D printed into houses in a way that generates 400 times less CO2 emissions than current builds.

In the simulated 3D printing of a home, the team found that using a reactive magnesium oxide mixed with thermal insulation and phase change materials (PCMs) lowered both its energy usage and environmental impact. If deployed on a wider scale, the engineers say the material could help make 3D printing a more attractive tool for tackling both housing shortages and the issue of climate change.

Cleaning up the construction industry

According to European Commission research, conventionally-constructed buildings account for 36% of all CO2 emissions generated in the EU. Of course, due to population increases, affordable housing construction is a necessity, but building these more sustainably is fast becoming a hot topic of research. These studies have often revolved around reducing the cooling and heating loads of buildings.

Doing so is seen as crucial to improving the sustainability of the house building process, as it could help lower the fuel requirements associated with their construction and heating. Previous research has found that one way to improve the thermal performance of such buildings is to 3D print them from PCMs, capable of absorbing heat within a specific range and managing internal temperatures.

However, the Tehran team says these PCMs have proven the ability to “enhance thermal capacity,” but their mechanical properties can decline, hindering their potential for end-use application. The engineers also claim that other materials, in which geo-polymer networks are infused into cement, have a mixed level of success on the environmental front, with some still having a high CO2 footprint.

3D printing cement more sustainably

To identify the optimal cement formula for 3D printing houses, the team investigated the performance of simulated builds, realized via magnesium oxide (RMC) and calcium sulfoaluminate (CSA) cements. Through the tests carried out via the DesignBuilder software, both proved capable of rapidly setting and showed high initial strength levels, but RMC had a higher compressive strength of 60 MPa.

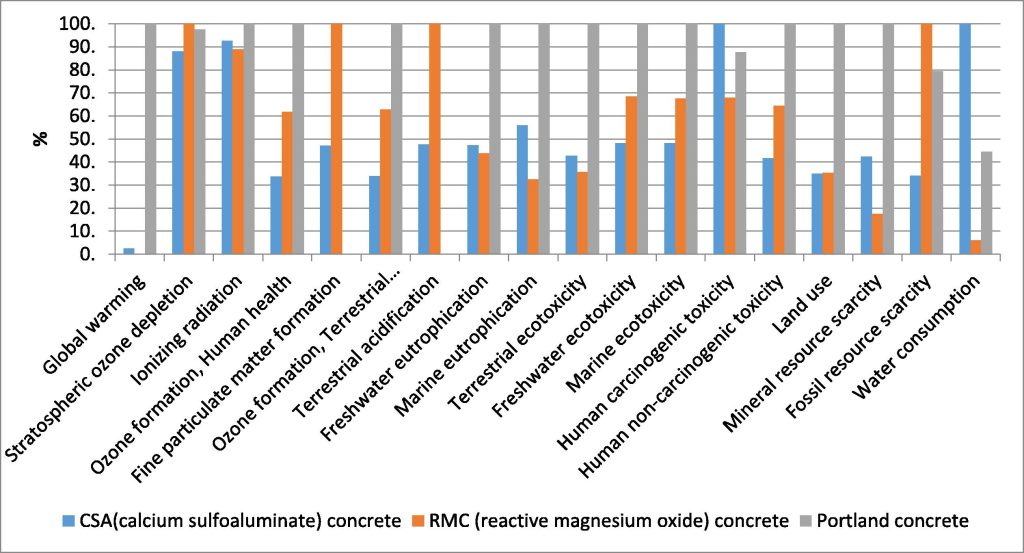

When it came to analyzing the sustainability of this virtual two-story build, the researchers opted to subject it to a full life cycle assessment (LCA), from shipping through to materials and electricity usage. As it turned out, the LCA’s results showed that both their cement formulations had a lower eco-impact than conventional portland cement, with CSA’s energy consumption being higher than that of RMC.

To make their materials more effective at managing internal temperatures, the engineers later added calcium chloride to the mixtures. Adding the compound enabled the mixtures to be 3D printed into concrete capable of absorbing and discharging heat when they hit a melting or freezing point. Supplementing RMC with foam in simulations also enhanced this effect, optimizing the building’s insulation.

Ultimately, the presence of magnesium was found to add to the carcinogenic toxicity of the house’s walls, but 3D printed RMC with insulation had the least ecological impact. As a result, the team concluded that 3D printing can “greatly help reduce the energy consumption” of construction in the future, even if their RMC remains quite water-intensive and has toxicity issues that need ironing out.

AM’s potential in self-cooling buildings

Significant research is being poured into optimizing the thermal efficiency of concrete 3D printed builds, especially in the field of construction materials. Researchers at Texas A&M University, for example, have developed 3D printing phase change materials that can be used to construct homes capable of passive internal temperature regulation.

In the past, Microlight3D has also received EU backing to develop concrete for creating ‘self-cooling’ buildings. Working with five European universities as part of the Future and Emerging Technologies (FET) program, the firm aims to design a microstructured material that combats the urban heat island phenomenon.

Elsewhere, a Swinburne University of Technology and Hebei University of Technology team has taken a different approach to make house building more eco-friendly. By developing a 3D printing material made from construction waste, the engineers hope to reduce the CO2 emissions of additively manufactured builds and the technology’s reliance on natural resources.

The researchers’ findings are detailed in their paper titled “Investigation of thermal performance and life-cycle assessment of a 3D printed building,” which was co-authored by Mahdi Ebrahimi, Mohammad Mohseni Alireza Aslani, and Rahim Zahedi.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our YouTube channel, featuring discussion, debriefs, and shots of 3D printing in action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a concrete 3D printer in action. Photo via Hamilton Labs.